Technology » Holographic measurement

Technology » Holographic measurement

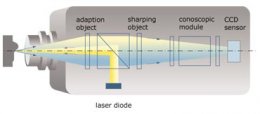

In classical holography an interference pattern is formed between an object beam and a reference beam using a coherent light source. The object beam and the reference beam propagate at the same velocity, but follow different geometrical paths, creating a Gabor Zone Lens (GZL).

However, in Conoscopic Holography the separate coherent beams are replaced by the ordinary and extraordinary components of a single beam traversing a uni-axial crystal. This produces holograms, even with incoherent light, with fringe periods that can be measured precisely to determine the exact distance to the point measured.

Conoscopy uses concentric optics and is insensitive to the position of the key optical components. Therefore, the CP1000 sensor is rugged and precise. The measurement scale can be changed by changing objective lens.

Diagram of the interferometric basic set-up

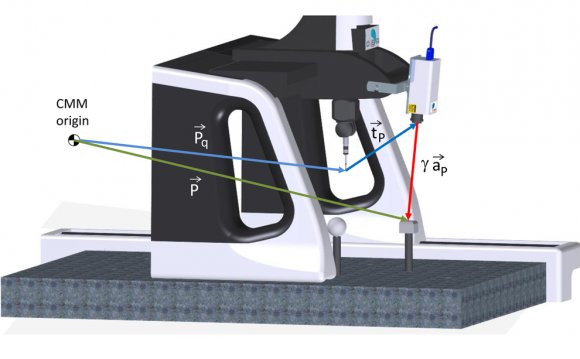

Measurement principle of the CP1000 sensor

The unique design of the CP1000 sensor, based on conoscopic holography technology permits measurement of narrow, deep holes and sharp angles. Since the CP1000 is collinear, even blind corners and sharp angles (up to 85 degrees) can be easily measured.

This enables the CP1000 sensor to fulfill different measurement tasks, i.e. measurement of screw threads or solder bump volumes.

|

H1 |

H2 |

H3 |

|

|

Focal length [mm] |

25 |

50 |

75 |

|

Absolute accuracy [µm] |

RELATED VIDEO